Diesel Systems High quality is the best customer care

Ships, locomotives, power generators, mining trucks, construction and agricultural machinery can all run in an economical, powerful and reliable way on diesel engines. No other combustion engine is used as widely as the diesel. Its high efficiency and associated fuel economy make it the preferred propulsion system for off-highway vehicles.

Why Bosch Diesel systems?

Bosch is a leading manufacturer of components for diesel engines in both the on-highway and off-highway segments and continually sets new standards with its diesel innovations. Bosch offers a comprehensive portfolio of high-quality components and systems for both segments. A large proportion of off-highway diesel engine and generator manufacturers take advantage of this and benefit from excellent power dynamics, low emissions and low fuel consumption.

Introduction and classification

Bosch, your reliable partner for diesel systems

Bosch is a constant, reliable partner throughout the lifecycle of Off-Highway and large engines: from the design and development of powertrain technology, through to large-scale production, all the way to spare parts supply and replacement solutions. Hence, Bosch consistently further develops diesel drive systems for use in on-highway as well as off-highway applications. These include components for fuel injection and fuel supply as well as the engine and air control and exhaust-gas treatment.

As a provider of complete systems, Bosch is familiar with the various technical requirements and offers the right injection system for each segment. Our experts support customers in finding the appropriate design for their specific application in terms of function, robustness, and economic efficiency. Thanks to its global presence, Bosch also appreciates the specific requirements of each market.

Classification of Off-Highway diesel engines

Bosch divides Off-Highway applications according to their engine power output in two segments.

One of the segments is the Off-Highway diesel engine segment, with engine power outputs between 19 kW and 560 kW.

The Off-Highway Large Engine (LE) segment is characterized by engine power outputs above 560 kW (inspired by the Stage V nonroad mobile machinery emission limits, source: Dieselnet). Large engines are typically characterized by engine displacements between 15 l and several 100 l, bore sizes between 150 mm to 500 mm and configurations from L8 to V20. Hence, the large engine segment includes a very broad variety of set-ups.

Off-Highway diesel engines (< 560 kW)

Bosch started producing inline injection pumps back in 1927.

The distributor injection pump (1962), the electronic diesel control (1987) and the control-sleeve inline fuel injection pump (1993), marked important milestones at the development of conventional diesel systems.

Original-equipment diesel competence

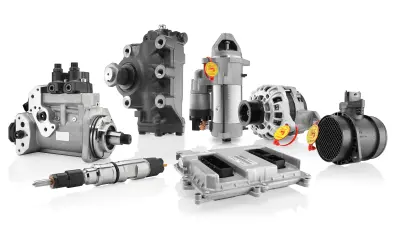

No matter whether common-rail or unit injector system, inline or distributor injection pump, Bosch innovations ensure powerful performance and efficient fuel combustion of and in millions of diesel engines. Bosch products and spare parts are based on the system know-how gained over decades. They need to meet high quality expectations. Workshops can thus be sure, they will always install modern and robust spare parts featuring well-known Bosch quality.

Global production of reliable spare parts

Bosch produces globally conventional and modern diesel systems and a comprehensive range of spare parts in case they need any repair. High-quality spare parts are a prerequisite for the high functionality of these systems. Bosch spare parts stand out for their high quality and reliability.

Hence, Bosch supplies workshops with a comprehensive range of parts for diesel injection systems; genuine spare parts as well as spare parts of equivalent quality for various OHW applications:

1) Pump elements

2) Injection nozzles

3) Pressure valves and valve sets

4) Rail-pressure sensors

5) Sealing kits

Further product portfolio and services for Off-Highway diesel engines:

-Innovative workshop equipment and software

-Practice-oriented service trainings

Off-Highway Large Engines (LE) (> 560 kW)

Big engines mean big opportunities

Market forecasts predict worldwide demand over the coming years in the segment of new and efficient large engines. One major driver of this phenomenon is the demand in growth markets. Manufacturers and dealers have the opportunity to open up new market segments and expand existing ones. However, conventional powertrain systems can help vehicles meet emissions limits only in conjunction with exhaust-gas treatment. Electronically controlled powertrain systems with common-rail injection are the key to greater cost effectiveness, reliability, and performance – both in the commercial vehicle segment as well as for large engines.

Bosch is systematically refining powertrain systems for large engines and offers comprehensive system know-how with consulting services and components that have proved their worth in large-scale production (Hallein, Austria - LE headquarters and biggest site). This includes control units and sensors for engine management as well as complete systems and components for fuel injection, gas ignition, gas injection, dual-fuel operation and exhaust-gas treatment.

In addition, the Bosch portfolio includes marine-certified versions of injection components, sensors and control units.

Customer benefits with Bosch LE parts

-Global presence: Bosch provides injection equipment and system control for large engines in many regions and for the key players in the large-engine business.

- Long-term partnership: Bosch is a constant, reliable partner throughout the lifecycle of large engines.

- Ensuring quality and reliability: To ensure reliable operation even under adverse environmental conditions and in difficult situations, Bosch designs its components – from injectors to pumps – to be particularly robust.

- System and network competence: As a provider of complete systems for large engines – from injection to exhaust-gas treatment – Bosch is familiar with their various technical requirements. Bosch understands the need for coordinated system design that takes into account all interrelationships, and meets this need with integrated solutions

- Comprehensive portfolio and know-how: Bosch offers the full span of injection systems and components – from the smallest one-cylinder engine with an output of a few kW up to large 20-cylinder engines with over 10000 kW. The portfolio covers a wide range of operating types that run on various fuel types.

Off-Highway diesel engines (< 560 kW)

Bosch products for your diesel engines below 560 kW

Conventional

Bosch is a supplier of OEM products and replacement parts for conventional systems.

Bosch is producing conventional systems since more than 90 years. These systems comprise of nozzleholder assemblies and mechanically/electronically controlled inline pumps or distributor pumps. Conventional systems are particularly robust. This is why they are often used in a range of off-highway applications. The injected fuel quantity can be quickly, evenly and simply varied.

Modern - Common-Rail systems

Bosch offers a broad spectrum of common-rail systems that delivers state-of-the-art answers to typical requirements. Bosch common-rail injectors for the off-highway segment work with pressures between 1400 and 2700 bar. The various types of common-rail pumps are suitable for use in a wide range of applications.

Customer benefits

-Same product in aftermarket as in OEM series, thus ensuring quality and longer maintenance intervals

-Fair-value-oriented customer solutions with new or remanufactured goods or replacement parts for repairs

-Worldwide production network

Off-Highway Large Engines (LE) (> 560 kW)

Bosch products for your diesel engines bigger than 560 kW

The huge variety of worldwide large engine requirements leads to a broad portfolio of Bosch products. The Bosch Large Engine (LE) portfolio includes mechanical/conventional solutions like PF pumps with NHA (Nozzle Holder Assemblies), electronically controlled single cylinder solutions like UP (Unit Pump) and UI (Unit Injector) as well as scalable Modular Common Rail systems (MCRS) with 1600 bar and 2200 bar system pressure.

Conventional

Bosch can draw on over 40 years of experience with mechanical fuel-injection systems for large engines. The Bosch PF single injection pump with a nozzle holder assembly for each engine cylinder is a particularly successful example among these. Due to the robust design, the PF pump can be operated with a large selection of fuel types.

Please visit the Bosch Mobility Solutions Website for further information and interactive graphics.

Modern - Common-Rail systems

In comparison with conventional fuel-injection systems, the modular common-rail systems (MCRS) from Bosch reduce the fuel consumption with a simultaneous reduction of running noise. They are designed for pressures between 1600 and 2200 bar and engines with up to 20 cylinders. The injection pressure is independent of engine speed.

Please visit the Bosch Mobility Solutions Website for further information and interactive graphics.

Customer benefits

- Stringently fulfills the OEM specifications

- Product options for use with different fuel types

- Robust and reliable, thanks to proven series-production technology

- Worldwide production network

For all information, presented on this webpage, applicable:

No legal advice - provided for informational purposes strictly on a non-reliance basis.

For further and detailed information about diesel and gas fuel injection equipment, please visit the Bosch Mobility Solutions Website.